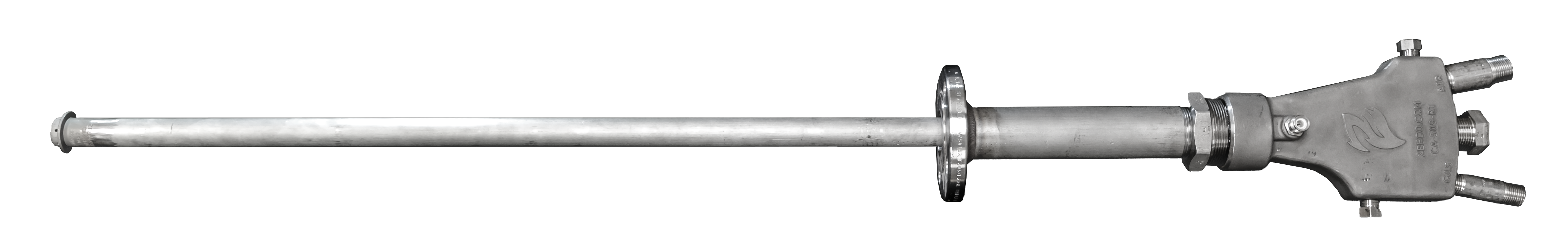

External Ignition Pilot

Reliable Light Off for Duct Burners, Boiler Burners, and Thermal Oxidizers

Avoid common pilot failures and ensure reliable light off for your burners with the ZEECO® External Ignition Pilot. Using proven technology, extensive test data, and customer feedback, Zeeco has developed an industry-leading pilot that consistently performs even in the harshest conditions while allowing easy maintenance without the need to shut down your burners. Since its development in early 2022, more than 300 External Ignition Pilots have been installed around the world.

GET IN TOUCH

How it works

The External Ignition Pilot is constructed with a 310 stainless steel nozzle inserted into a furnace and an external module made of 304 stainless steel with connections for gas, air, and an electrical ignitor. Gas and air are premixed in the external module and ignited, producing reliable light off and a robust pilot flame.

Why External Ignition?

By keeping the ignition source away from the pilot flame, Zeeco avoids many issues associated with traditional internal ignition pilots, including electronic circuit shorts, broken components, and water condensation. Because ignition happens in the external module, only the nozzle is subject to internal furnace conditions.

Quick and Easy Maintenance

Maintenance of the External Ignition Pilot was designed to be as simple as possible. Operators only need to disconnect the air, gas, and electrical components to replace the electronic ignitor. All this can be done while the burner is in operation. The internal nozzle rarely needs maintenance, but if required, operators can simply remove the nozzle, disconnect it from the external module and replace it with a new internal nozzle.