Zeeco Power Burners

Applied Knowledge is Powerful

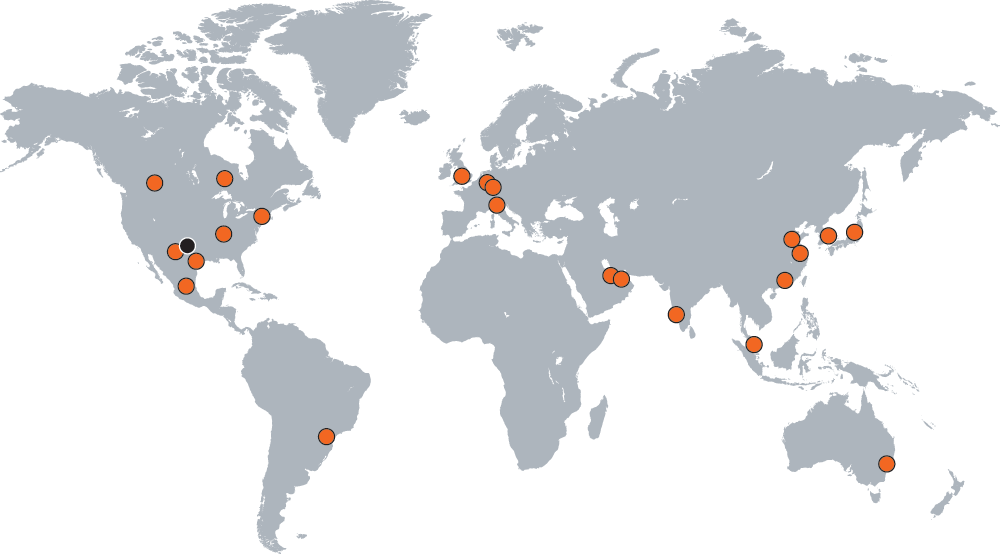

Since 1979, Zeeco has taken steps to provide our customers with advanced combustion and environmental solutions. Our Power Division, based in Plainville, Connecticut, is made up of experts in their field with decades of experience working with burners for power and steam generation applications across the world. When you choose Zeeco, you're choosing to work with the best in the industry.

GET IN TOUCH

Boiler and Duct Burners

ZEECO boiler and duct burners are designed to be stable, reliable, and achieve low emissions over a wide range of firing conditions for various applications in industries ranging from power and petrochemical plants to refineries and pulp and paper plants.

Our power burner product and support product lines include:

ZEECO FREE JET and the ZEECO GB Burners, ZEECO TEG+, ZEECO register-style duct burners, physical airflow modeling, CFD, and pilots and ignition systems.

Click a photo to learn more about an individual product.

Power Services & Aftermarket Parts

Zeeco's Power group is capable of providing end-to-end solutions for your boiler and duct burner needs. Whether you need replacement parts, control and safety systems, or a new burner altogether, Zeeco can deliver.

Click a photo to learn more about an individual service.

Other Resources

Power Aftermarket Products

It doesn’t matter if your equipment was manufactured by Zeeco or another combustion equipment supplier. We have what you need to restore, and often improve, the efficiency, functionality, as well

Power Brochure

Read about Zeeco's expansive capabilities in the Power and Boiler burner market

FREE JET® Power Burner

The ZEECO® GLSF FREE JET® power burner is one example of our relentless commitment to help steam-generating industries

GB - Low NOx Burner

The ZEECO® GB Burner is engineered to solve complex issues, simply. This axial, parallel-flow, register-type burner, is based on a design proven in the combustion industry for more than 40 years.

Process and Boiler Burner Upgrades, Retrofits, & Controls

Upgrading your process heaters or boilers can dramatically improve plant safety, reduce NOx emissions, maximise plant efficiency, and enable easier fuel changes.

_IMG_2095-CMYK.jpg)